“EnerMech’s collaboration with the ECITB exemplifies how industry partnerships can elevate workforce capability. By delivering ECITB-approved MJI training and testing, we ensure our engineering construction professionals are equipped with the skills and confidence to perform critical tasks to the highest standards.”

That’s the view of Jenni Batchelor, Head of Training at EnerMech Ltd, on how the Engineering Construction Industry Training Board’s (ECITB) four-stage model of training and testing enhances mechanical joint integrity (MJI) competency at the company.

The MJI scheme has been one of the ECITB’s most used products since it was developed in partnership with industry experts in 2011.

In the 18 months from the start of 2024, more than 5,400 workers attended this training in Great Britain and over 5,500 internationally, with employers and providers valuing the “rigorous” nature of the training and testing.

MJI gives the skills and knowledge to do controlled and verified bolting activities on a variety of assemblies, including flanges, clamps and wind turbines. These skills ensure that, regardless of the medium being transported in the pipes, the risk of leaks is eliminated or that wind turbine assemblies are installed effectively.

The skill is crucial across craft and technical trades in engineering construction and essential for preventing environmental damage, safety incidents and costly downtime.

Unique perspective

EnerMech is a global specialist in integrated mechanical, electrical, instrumentation and integrity services, operating across numerous sectors in the engineering construction industry (ECI).

It is also an ECITB-approved training provider. This includes training and testing its workers to ECITB MJI standards to deliver mechanical bolting services.

“We are deeply committed to raising the bar in workforce competence and safety. Our training team has long been a strong advocate of the ECITB’s internationally recognised standards.

“Our collaboration with the ECITB on the MJI training and testing standards ensures our training solutions consistently meet – and often exceed – the expectations of the engineering construction industry, particularly in high-risk sectors such as oil and gas and petrochemicals.

“We trust in the rigour of this training, the on-the-job experience it fosters and the competence-based testing it includes.

“Our approach to collaboration with the ECITB is hands-on and practical. As both an approved training provider and an international employer, we offer a unique perspective. This dual role allows us to contribute meaningfully to course development and industry forums, drawing on our experience in both training delivery and real-world mechanical joint integrity services.”

Jenni Batchelor

Head of Training at EnerMech

MJI four-stage model

The ECITB’s four-stage model is made up of the following steps:

- ECITB-approved classroom and practical training.

- Completion of a logbook that provides evidence of consolidation of learning on site before competency test attendance.

- Completion of the relevant ECITB technical test(s) to demonstrate competence in safely dismantling and assembling a range of different types of pipe flanges, clamps and bolted connections.

- Reassessment by a technical test every three years to demonstrate continuing technical competence.

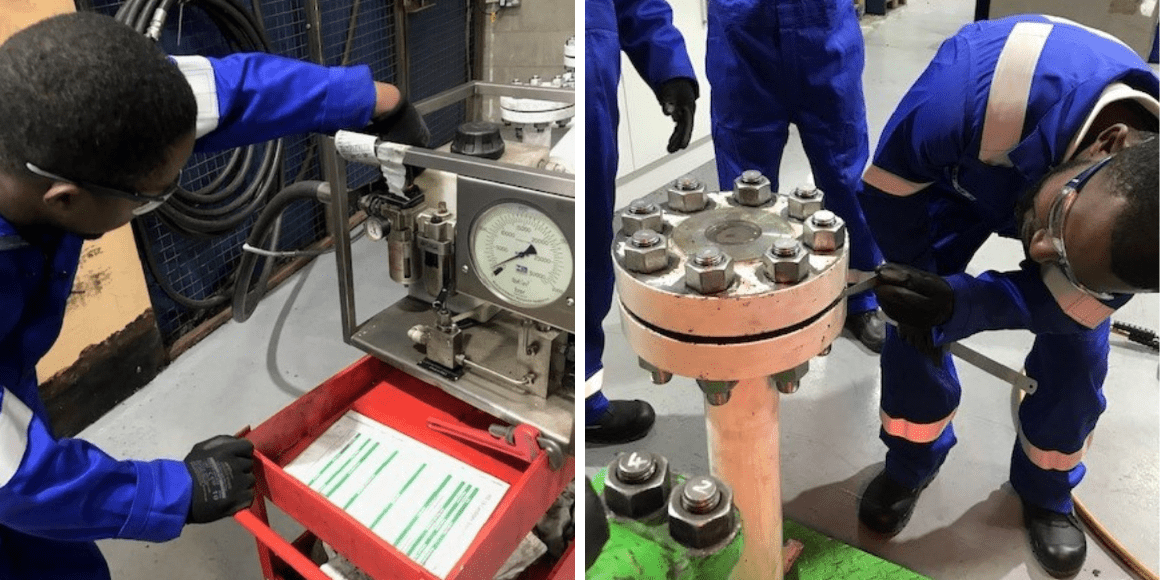

Pictured here, above and below: MJI training and testing taking place at EnerMech.

Helping avoid complacency

Process Field Supervisor Scott Mitchell, who has worked for EnerMech since 2011, is well-versed at completing these four stages.

He works in the company’s process division, which provides project management and oversight of offshore topsides’ process systems, specialising in nitrogen and testing services, flange management and bolting, oil flushing and chemical cleaning.

Having worked in industry for 20 years, firstly as a technician and now as a supervisor, Scott has been through the ECITB scheme several times to demonstrate his bolting competence.

He said: “The ECITB’s MJI process is well known in industry. It has been good in setting a standard and helping to avoid complacency.

“Before the ECITB process was developed, other training schemes I did gave me a lifetime certificate. So, once you had it, nobody questioned it.

“Over time, people can pick up bad habits which become routine. The good thing about the ECITB’s testing is every three years you go back and any bad habits get picked up on.”

Flexibility of MJI training and testing scheme

Mechanical joint integrity is applicable across a wide range of ECI sectors.

The MJI training standards, tests and logbooks are regularly reviewed by a working group made up of employers, subject matter experts and ECITB-approved training providers to ensure they remain current and relevant to industry needs.

Revisions made ensure that safe bolting techniques are implemented to protect both workers and employers’ assets.

“The flexibility of the MJI scheme allows us to cross-skill employees from other departments as well as fast-track trainee technicians to prepare them for offshore careers,” says Jenni.

“ECITB MJI training and testing are invaluable in ensuring consistent, high-quality training across our workforce at EnerMech. Knowing that all personnel have followed the same rigorous path to competence gives our clients confidence in the services we provide.

“It also allows us to structure career development in a way that is transferable across the many industries we serve.”

Sign up for updates

Your information will be used to subscribe you to our e-newsletter.

For more information, please see our Privacy Notice.